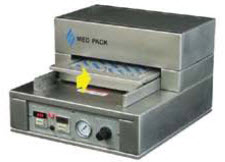

Blister Sealers | Preferred Pack MEDPACK MB6X9 Blister Sealer

Call Toll Free: 877.336.6877 for Pricing

Availability

Online

In Store

Same Day

Description

Blister Sealers | Preferred Pack MEDPACK MB6X9 Blister Sealer

The MEDPACK MB6X9 tray sealer has been engineered for reliability, high productivity and efficient use of space and energy. This medical tray sealer is ideally suited to meet your requirements for speed , accuracy and flexibility of operation . Automatic operation, self aligning pressure system, and balanced heat platen assure consistent sealing of materials. MEDPACK equipment is designed for continuous production use with a minimum of operator skill. From it's stainless steel construction to it's digital controls, the MEDPACK MB6X9 is "The Professional's Choice".

Examples Of Out standing Standard Feat ures Include

1. Fully enclosed sealing chamber (Safe Operation).

2. Instant fixture change over - No tools required [True Drop-In Tooling).

3. Stationary heating platen with stainless steel sealing face.

Standard Features

- Balanced Heating Platen

- Self Aligning Pressure System

- Powder Coated Industrial Finish

- Fully Enclosed Sealing Chamber

- Low Cost Tooling

- 1800 lbs Sealing Force

- All Steel Construction

- Adjustable Pressure Regulator

- Electronic Timing System

- Industrial Quality

- Stainless Steel Sealing Face

- Pressure Gauge

- Fully Adjustable Thermostat

- Low Power Consumption

- Fast Cycle Times​

Specifications:

- Sealing Area: 6inch X 9inch

- Maximum Card Size: 7 1/2inch X 10 1/2inch

- Maximum Blister/Tray Depth: 1 1/2 inch

- Available Sealing Force: 1800 Lbs.@100 PSI

- Temperature Control: Ambient To 50O°F

- Electrical: 110 VAC/6.5 A/1 PH/60 HZ

- Minimum Air Requirement: 40 PSI

- Shipping Weight: 86 LBS.

Operating sequence:

-

1. Load Tray, package contents, Tyvek, foil or medical lids into the sealing fixture

2. Slide shuttle completely into sealing chamber.

3. Automatic heat and pressure cycle seals tray to lidding material.

4. Slide fixtur e shuttle out of the sealing chamber.

5. Remove finished package and reload for next cycle.

COVID Supply Chain Warning Due to global challenges including COVID and Climate Change affecting all businesses, prices are subject to change because of supply chain disruptions, shipping delays, labor shortages, material shortages, and inflationary pressures. If you place an order, and there is an increase in a price from that shown, we will alert you before processing the order.