Back To Buyer's Guide

What are Binders?

What are Binders?

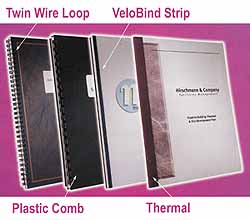

Binders are machines that align, punch, and enclose individual sheets of paper using a specific technology to "bind" sheets in to a "document set." There are a number of binding technologies across many price points that will accommodate virtually any document presentation requirement. Binding typically entails a three or four step process.

In the first step, sheets are sized (trimmed) or selected from pre-sized stock and printed, before or after the trimming process. To bind the sheets together, they must first be punched (hand crank or electric) along the edge with a number of holes depending on the "bind strip" to be used. The punch is often built into the binding machine. Finally, protective covers are added, cover and sheets are aligned, the bind strip is inserted/applied (either manually or electrically) and the document is closed.

Binding documents is a great way to add a professional look to client presentations, annual reports or technical manuals. Binding also protects documents and assures their long-term usage. Solutions are available for binding just a few pages or several hundred pages.

Choosing the Right Binding Technology

Presentation effect, production speed, and number of pages per bind will determine which binding technology is best suited for a particular application.

Binding machines are manufactured in electric, semi-automatic, and manual models. Beyond the issue of manual versus electric, binder performance is determined by the variety of binding supplies, effort required to produce a document set, the number of sheets that can be bound in one effort, and the number of binds that can be achieved in a given period of time. Some binders only bind while others punch and bind. Some binding technologies allow the document set to be edited (pages added or removed). There are binding machines that deliver products of outstanding quality a few at a time and binding machines that churn out hundreds of products per hour with generic quality.

To choose the right binding machine, you must clearly identify the type, quality and appearance of the finished product.

Factors to Consider Types of Binders

Types of Binders

Coil(Spiral) - Wire & Plastic

Coil or Spiral Binders are the most recognizable type of binding technology. Spiral binding has been available for many years in the form of spiral notebooks and steno pads. Wire binding coils come in a limited choice of colors, in maximum lengths of 12", and can bind documents up to approximately 1" thick. Wire coil binding machines, also known as wire inserters, are available in tabletop and floor standing models. The end of a long wire is inserted into the machine, where it coils in and out of the punched holes. Some machines will cut and crimp the edges automatically, while other machines require that the operator use a pair of finishing pliers to cut and crimp the wire.

Plastic coil binding is relatively new, but is being well accepted. The application of plastic binding is identical to wire binding with a few advantages. Plastic bind strips are available in much longer lengths (up to 36"), come in a wider variety of colors, and are easier to close. With plastic binding, greater presentation design is possible and the cost of machines and supplies is less than with wire.

You can expect to spend between $200 and $400 for a manual coil binder that punches up to twelve sheets and binds up to ??" thickness. Electric coil binders cost between $500 and several thousand dollars depending on the number of sheets punched and binding thickness.

Plastic Comb

The most popular binding technology, plastic comb binding offers some unique properties.

Plastic combs are the least expensive of all bindings. Comb bind strips are easy to assemble, durable, available in a wide variety of colors, and will bind documents from ??" to 2" thick. Most importantly, comb-bound documents may be reopened to remove or insert pages. One drawback is that plastic comb bind strips are sold in maximum lengths of 11".

Comb binders are the most affordable binding systems. Manual systems costing as little as $150 will punch 5-7 pages and bind up to twenty pages. Higher end models are typically priced under two thousand dollars.

Wire Loop

When an impressive presentation is key, "Double Loop Wire" binding makes a clear statement of quality. Although the operational costs are a bit more than other forms of binding, your clients will appreciate the difference. Double loop wire offers a clean, consistent appearance. Once the wire loop is inserted into the document, it is then closed either by the same binding machine or by a separate closer. The use of an additional closing machine will depend on the manufacturer. Wire loop bind strips are available in several colors and lengths up to 11", and will bind document sets from ??" to 1" thick.

Wire loop bind strips can also be used in most plastic comb bind machines. Most wire loop binding machines are reasonably priced between $500 and $1,000.

Velo

Velo binding does not use coils, loops, or comb strips to close bind documents. Instead, Velo binding is a process where holes are punched into the pages and two long fabric-like strips of plastic are applied to hold the document together. Velo bind systems will bind documents up to 15" long in limited numbers. The real strength of velo binding is speed.

For standard document sizes (8.5"x11"), velo bind machines come in both manual and automatic models. Higher-end models are capable of feeding, punching and binding up to 18,000 sheets per hour into more than 700 sheet bound documents. Additionally, as with plastic comb binding, Velo binds strips can be opened and refastened so pages can be added or removed.

Although velo binders are available as low-end solutions, most are manufactured as high production units and are sold from $3,000 up to $10,000 for units that will bind hundreds of document sets per hour.

Thermal (Tape)

Thermal and tape binding uses thermal glue, either in a wrap-around cover (thermal) with integral glue strip or tape coated with thermal glue (tape). It is a relatively economical form of binding and lends itself well to mass production, especially when long runs of the same document are being bound.

Both thermal and tape binding machines can accommodate documents from 5 to 500 sheets (2.25" thick). Most machines come with a little "start-up" adhesive, but the user must purchase adhesive separately from the machine. The wrap-around cover or perfect bind is the common paperback book. Pages are glued along the edge so no punching is required. After the adhesive has been applied, the machine will trim any excess materials from the document. Pages may be added or replaced by reheating the glue in a thermal binding machine and simply inserting or removing pages. For tape binding, the control panel on the machine will inform the user of which tape size should be used based on the thickness of the document. The tape bind will be glued to the outside spine of the cover securing the document, as opposed to thermal binding where the bind is a part of the cover that wraps around the document.

Much like velo binders, thermal and tape binders are available as low-end solutions. However, most are manufactured as high production units and are sold from $3,000 up to $10,000 for units that will bind hundreds of document sets per hour.

Additional Binding Options

Binding Punches

Binding punches punch holes in documents either manually or electronically. Manual punches usually punch as many as 10 to 15 sheets per punch, while electric punches usually punch anywhere up to 17 or even as many as 45 sheets per punch depending on the model. Although separate from one another, punching machines are intended to be used in tandem with binding machines. In some cases, the machines physically attach to one another for a complete punch and bind station. Buying a separate punching machine is a good idea for high volume punch demands because it can free up combined punching and binding machines, while increasing output.

Bindery Staplers

Bindery staplers are made for stapling together extra thick documents containing as many as 250 sheets. Manual models can staple more sheets than electric models. A foot pedal for extra stapling strength often powers stronger manual bindery staplers. One important consideration for bindery staplers is their throat depth. If documents need to be saddle stapled, a bindery stapler with a long throat depth is preferable. Bindery staplers are a good idea for quick and simple assembly of documents. They are easy to use and take up very little space. The downside is that presentation quality isn???t as nice as with other binding options and documents are more easily loosened from the bind.

Padding Presses

Padding presses use adhesive glue to make "pads" out of stacks of paper. Padding presses are perfect for padding carbonless forms, note pads, and scratch pads. A clamp secures the paper to the base of the machine, where the glue is applied to one end of the stack. Once the glue has dried, the stack can be cut into individual pads. The biggest consideration when looking to purchase a padding press is the height of the stack that the padding press can handle. Some padding presses can only pad stacks up to 5.75", while better models can pad stacks up to approximately 20".

Glossary

Binders are machines that align, punch, and enclose individual sheets of paper using a specific technology to "bind" sheets in to a "document set." There are a number of binding technologies across many price points that will accommodate virtually any document presentation requirement. Binding typically entails a three or four step process.

In the first step, sheets are sized (trimmed) or selected from pre-sized stock and printed, before or after the trimming process. To bind the sheets together, they must first be punched (hand crank or electric) along the edge with a number of holes depending on the "bind strip" to be used. The punch is often built into the binding machine. Finally, protective covers are added, cover and sheets are aligned, the bind strip is inserted/applied (either manually or electrically) and the document is closed.

Binding documents is a great way to add a professional look to client presentations, annual reports or technical manuals. Binding also protects documents and assures their long-term usage. Solutions are available for binding just a few pages or several hundred pages.

Choosing the Right Binding Technology

Presentation effect, production speed, and number of pages per bind will determine which binding technology is best suited for a particular application.

Binding machines are manufactured in electric, semi-automatic, and manual models. Beyond the issue of manual versus electric, binder performance is determined by the variety of binding supplies, effort required to produce a document set, the number of sheets that can be bound in one effort, and the number of binds that can be achieved in a given period of time. Some binders only bind while others punch and bind. Some binding technologies allow the document set to be edited (pages added or removed). There are binding machines that deliver products of outstanding quality a few at a time and binding machines that churn out hundreds of products per hour with generic quality.

To choose the right binding machine, you must clearly identify the type, quality and appearance of the finished product.

Factors to Consider

-

How many sheets will need to be bound at one time?

Within each type of binding, there is a range of pages that can be bound into a document. Between binding styles, velo binding machines have the greatest binding capacity at 3" thick, whereas coil and wire loop binding can only bind documents up to 1" thick.

-

How many sheets will need to be punched at one time?

Just like binding capacity, punching capacity will range within each style of binding as well as between binding styles. Comb binding machines can punch in upwards of 30 sheets per punch, while coil binding machines can only punch up to 15 sheets per punch. Punching is not a concern for thermal binding machines.

-

What production capacity is required (binds per hour/day)?

The production capacity will vary within and between binding styles as well. The binding process will take longer for larger documents, as more sheets have to be punched and aligned.

-

Will editing be required later?

This is an important consideration for documents that are more prone to needing pages added or removed. Some binding styles, such as comb and velo, enable you to open the document, replace sheets, and reclose the document quite easily, while other binding styles, such as thermal and tape, require more work to edit.

-

What look is desired for finished documents?

The look of the finished document will be determined by what style is most suitable for your binding needs, as well as the use of the bound documents. Some binding styles such coil, comb, and wire loop allow the documents to lay flat, while velo and thermal binding, typically used for thicker documents, do not have lay-flat capabilities.

Coil(Spiral) - Wire & Plastic

Coil or Spiral Binders are the most recognizable type of binding technology. Spiral binding has been available for many years in the form of spiral notebooks and steno pads. Wire binding coils come in a limited choice of colors, in maximum lengths of 12", and can bind documents up to approximately 1" thick. Wire coil binding machines, also known as wire inserters, are available in tabletop and floor standing models. The end of a long wire is inserted into the machine, where it coils in and out of the punched holes. Some machines will cut and crimp the edges automatically, while other machines require that the operator use a pair of finishing pliers to cut and crimp the wire.

Plastic coil binding is relatively new, but is being well accepted. The application of plastic binding is identical to wire binding with a few advantages. Plastic bind strips are available in much longer lengths (up to 36"), come in a wider variety of colors, and are easier to close. With plastic binding, greater presentation design is possible and the cost of machines and supplies is less than with wire.

You can expect to spend between $200 and $400 for a manual coil binder that punches up to twelve sheets and binds up to ??" thickness. Electric coil binders cost between $500 and several thousand dollars depending on the number of sheets punched and binding thickness.

Plastic Comb

The most popular binding technology, plastic comb binding offers some unique properties.

Plastic combs are the least expensive of all bindings. Comb bind strips are easy to assemble, durable, available in a wide variety of colors, and will bind documents from ??" to 2" thick. Most importantly, comb-bound documents may be reopened to remove or insert pages. One drawback is that plastic comb bind strips are sold in maximum lengths of 11".

Comb binders are the most affordable binding systems. Manual systems costing as little as $150 will punch 5-7 pages and bind up to twenty pages. Higher end models are typically priced under two thousand dollars.

Wire Loop

When an impressive presentation is key, "Double Loop Wire" binding makes a clear statement of quality. Although the operational costs are a bit more than other forms of binding, your clients will appreciate the difference. Double loop wire offers a clean, consistent appearance. Once the wire loop is inserted into the document, it is then closed either by the same binding machine or by a separate closer. The use of an additional closing machine will depend on the manufacturer. Wire loop bind strips are available in several colors and lengths up to 11", and will bind document sets from ??" to 1" thick.

Wire loop bind strips can also be used in most plastic comb bind machines. Most wire loop binding machines are reasonably priced between $500 and $1,000.

Velo

Velo binding does not use coils, loops, or comb strips to close bind documents. Instead, Velo binding is a process where holes are punched into the pages and two long fabric-like strips of plastic are applied to hold the document together. Velo bind systems will bind documents up to 15" long in limited numbers. The real strength of velo binding is speed.

For standard document sizes (8.5"x11"), velo bind machines come in both manual and automatic models. Higher-end models are capable of feeding, punching and binding up to 18,000 sheets per hour into more than 700 sheet bound documents. Additionally, as with plastic comb binding, Velo binds strips can be opened and refastened so pages can be added or removed.

Although velo binders are available as low-end solutions, most are manufactured as high production units and are sold from $3,000 up to $10,000 for units that will bind hundreds of document sets per hour.

Thermal (Tape)

Thermal and tape binding uses thermal glue, either in a wrap-around cover (thermal) with integral glue strip or tape coated with thermal glue (tape). It is a relatively economical form of binding and lends itself well to mass production, especially when long runs of the same document are being bound.

Both thermal and tape binding machines can accommodate documents from 5 to 500 sheets (2.25" thick). Most machines come with a little "start-up" adhesive, but the user must purchase adhesive separately from the machine. The wrap-around cover or perfect bind is the common paperback book. Pages are glued along the edge so no punching is required. After the adhesive has been applied, the machine will trim any excess materials from the document. Pages may be added or replaced by reheating the glue in a thermal binding machine and simply inserting or removing pages. For tape binding, the control panel on the machine will inform the user of which tape size should be used based on the thickness of the document. The tape bind will be glued to the outside spine of the cover securing the document, as opposed to thermal binding where the bind is a part of the cover that wraps around the document.

Much like velo binders, thermal and tape binders are available as low-end solutions. However, most are manufactured as high production units and are sold from $3,000 up to $10,000 for units that will bind hundreds of document sets per hour.

Additional Binding Options

Binding Punches

Binding punches punch holes in documents either manually or electronically. Manual punches usually punch as many as 10 to 15 sheets per punch, while electric punches usually punch anywhere up to 17 or even as many as 45 sheets per punch depending on the model. Although separate from one another, punching machines are intended to be used in tandem with binding machines. In some cases, the machines physically attach to one another for a complete punch and bind station. Buying a separate punching machine is a good idea for high volume punch demands because it can free up combined punching and binding machines, while increasing output.

Bindery Staplers

Bindery staplers are made for stapling together extra thick documents containing as many as 250 sheets. Manual models can staple more sheets than electric models. A foot pedal for extra stapling strength often powers stronger manual bindery staplers. One important consideration for bindery staplers is their throat depth. If documents need to be saddle stapled, a bindery stapler with a long throat depth is preferable. Bindery staplers are a good idea for quick and simple assembly of documents. They are easy to use and take up very little space. The downside is that presentation quality isn???t as nice as with other binding options and documents are more easily loosened from the bind.

Padding Presses

Padding presses use adhesive glue to make "pads" out of stacks of paper. Padding presses are perfect for padding carbonless forms, note pads, and scratch pads. A clamp secures the paper to the base of the machine, where the glue is applied to one end of the stack. Once the glue has dried, the stack can be cut into individual pads. The biggest consideration when looking to purchase a padding press is the height of the stack that the padding press can handle. Some padding presses can only pad stacks up to 5.75", while better models can pad stacks up to approximately 20".

Glossary

- Alignment Guide: Assists user in setting pages for proper punching.

- Bind Strip: The type of binding used to connect individual sheets into a bound document (comb, spiral, tape).

- Comb Size Selector: Permits the usage of various comb sizes for binding.

- Comb Spreader Control: Keeps combs spread evenly ensuring the quality and durability of the bind.

- Cooling Tray: Lets bound documents dry and solidify while they stack onto one another.

- Dies: The actual spokes that punch the holes into the paper.

- Document Set: A number of individual sheets bound together.

- Double Loop Wire (Twin-Loop): Wire bind strip inserted two loops per punched hole.

- Fixed Margin Depth: Aligns paper in standard punching position.

- Jog Plate: Warms adhesive for thermal binding.

- Mandrels: The spindle or axle used to secure or support the material being bound.

- Maximum Binding Length: The longest length of paper that the machine can handle.

- Maximum Binding Thickness: The largest width capacity of the edge of a document.

- Punch: Incorporated or standalone device punches holes in to sheets before bind strips are inserted.

- Perfect Binding: A type of thermal binding in which documents are bound around the edge with a "wrap-around" look, commonly known as paperback.

- (Variable) Margin Depth Selector: Allows the user to punch holes in various distances from the margin of the page.

- Vertical Book Placement: Allows the user to insert documents without the hassle of placing them horizontally.

- Waste Tray: Collects excess chads from punching.