ACSI Model LPB MEDIUM DUTY SLIDER BED BELT CONVEYOR

Call Toll Free: 877.336.6877 for Pricing

Availability

Online

In Store

Same Day

Description

ACSI Model LPB MEDIUM DUTY SLIDER BED BELT CONVEYOR

Applications / Features:

- Packing

- Inspecting

- Sorting

- Assembly

- Testing

- Transporting

STANDARD SPECIFICATIONS

- Belt – 8 Inches, 12 Inches, 18 Inches, 20 Inches, 24 Inches and 30 Inches Black PVC 120 Belt.

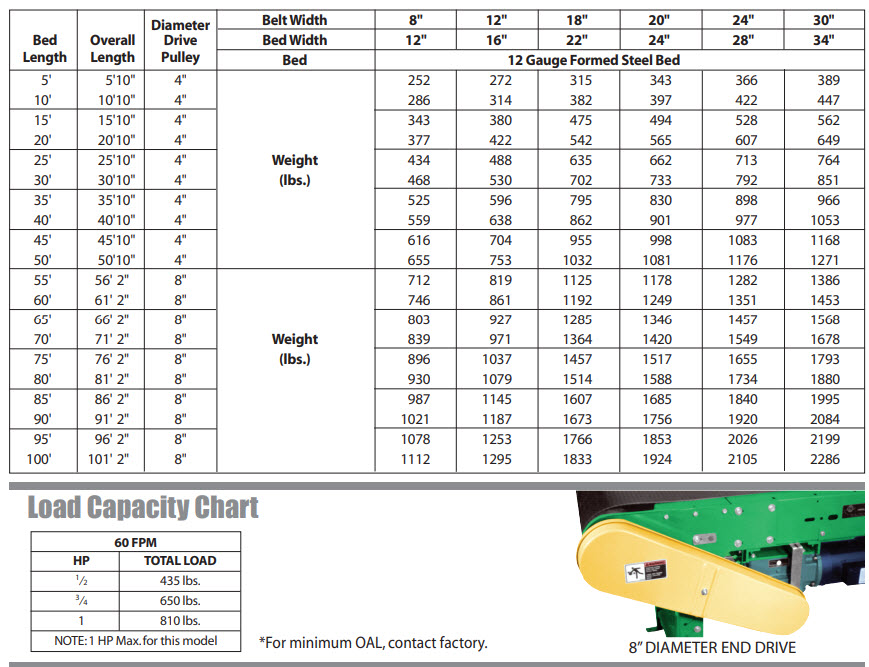

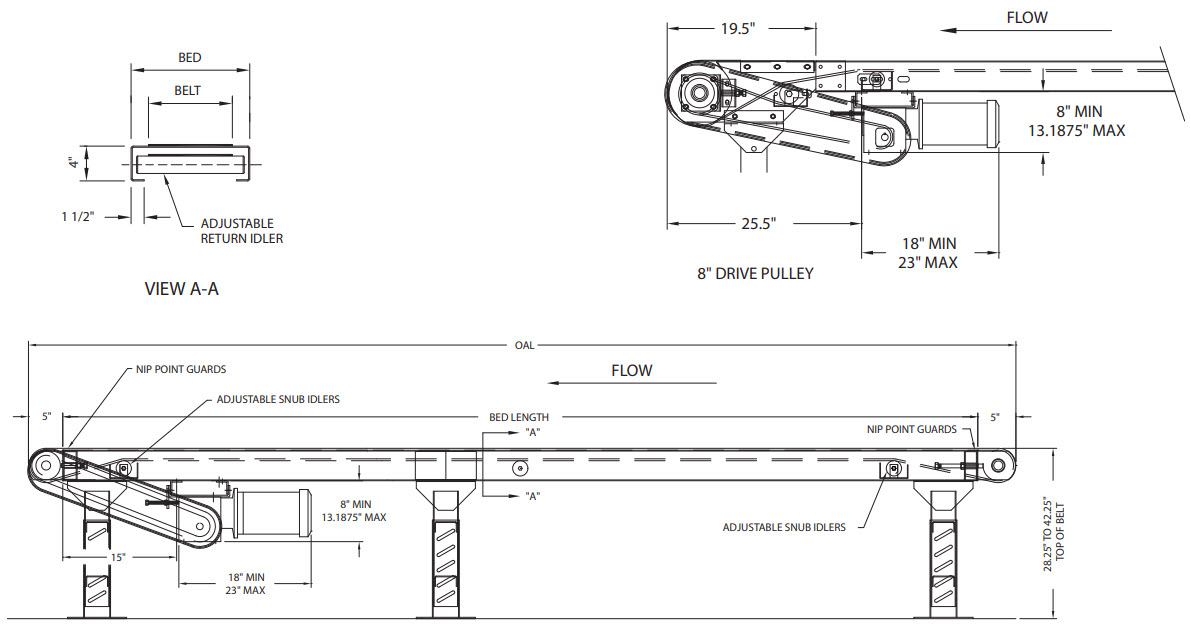

- Bed – 12 gauge powder painted formed steel, 4 Inches deep. Bed sections are 5 feet and 10 feet long, bolted together with spice plates and floor supports.

- Tail Pulley – 4 Inches diameter crowned with 1-3/16 Inches diameter shaft.

- Drive Pulley – 4 Inches diameter and 8 Inches diameter crowned and fully lagged. 4 Inches diameter pulley with 1-3/16 Inches diameter shaft, 8 Inches diameter pulley with 1-7/16 Inches diameter shaft.

- Snub Roller – 2 Inches diameter (for 4 Inches diameter drive pulley), 2-1/2 Inches diameter (for 8 Inches diameter drive pulley).

- Return Roller – 1.9 Inches diameter adjustable on 10’0 Inches centers.

- Floor Supports – Adjustable 28-1/2 Inches to 42-1/2 Inches from floor to top of belt. One support supplied at each end of conveyor and at each bed joint.

- Take-Up – 6 Inches long screws located at tail pulley to provide belt tension.

- Bearings – Sealed and pre-lubricated with cast iron housings.

- Speed Reducer – C-Face mounted heavy duty worm gear reducer.

- Motor – 1/2 HP 230/460-3-60 TE motor.

- Belt Speed – 60 FPM constant.

- Capacity – Maximum load per lineal foot of conveyor – 75 lbs. Not to exceed Load Capacity Chart (see catalog page). (For Optional Equipment, Weight Specifications, and Engineering Line Drawings, please see catalog pages, above).

OPTIONAL EQUIPMENT

- Belt – Nitrile (white or black) with smooth top cover, Black PVC rough top, Brown Nitrile rough top. Special belts on application.

- Side Tables – 10 Inches, 16 Inches or 22 Inches wide formed steel side tables provide 12 Inches, 18 Inches or 24 Inches work area. Tables are supported by angles bolted to bed section.

- Guard Rails – Adjustable channel, continuous channel, or solid steel guard rails available.

- Floor Supports – Lower or higher than standard. Castered supports with 4 Inches diameter or 6 Inches diameter rigid or swivel casters.

- Ceiling Hangers – 1?2 Inches diameter threaded rods 8 feet long with locking nuts and mounting hardware. Other lengths are available.

- Gravity Conveyor Brackets – Adjustable bracket with 13?8 Inches diameter pop-out roller for attaching wheel or roller conveyor.

- Nose-Over – Adjustable single or double nose-over provides smooth transfer from incline to horizontal. See drawing on page 96 for details.

- Center Drive – Mounted below conveyor bed section. Can be placed most anywhere in conveyor length.

- Side Mounted Drive – End drive mounted to side of conveyor section. Specify side. Minimum 6 Inches elevation with 4 Inches drive pulley, minimum 9 Inches elevation with 8 Inches drive pulley.

- Overhead Drive – End drive mounted above conveyor. Specify clearance required.

- Auxiliary Take-Up – Mounted below conveyor bed section. Can be placed most anywhere in conveyor length.

- Motor – Single phase, energy efficient, explosion proof, etc. Other HP available.

- Belt Speed – Constant and variable belt speeds available.

- Electrical Controls – Magnetic starters and push button stations; manual motor starters with overload protection, others.

COVID Supply Chain Warning Due to global challenges including COVID and Climate Change affecting all businesses, prices are subject to change because of supply chain disruptions, shipping delays, labor shortages, material shortages, and inflationary pressures. If you place an order, and there is an increase in a price from that shown, we will alert you before processing the order.

Specifications

| Manufacturer Part #: | LPB |