The MGX Carton Former and Erector for Small and Medium-Sized Businesses

Description

The MGX Carton Former and Erector Designed Specifically for Small and Medium-Sized Businesses

Handling inflation, a slower economy, and recruiting quality talent amongst a labor shortage are all challenges many small and medium-sized businesses face in 2023. As business leaders face the issues of how to increase efficiency and reduce costs among these challenges, automated packaging solutions are something to consider.Carton-forming machines are one part of automated packaging solutions that can help your small business increase efficiency and reduce the time-consuming labor associated with forming, erecting and filling cartons by hand.

Benefits of cartoning machines

Automating the packaging process comes with many benefits. Cartoning machines can:- Help your business save money. Cartoning equipment requires minimal human intervention, allowing your employees to focus on other essential operations in your manufacturing process.

- Allow you to possibly double or even triple your current output, increasing efficiency and reducing your labor costs.

- Increase your quality. Significantly reduce your packaging error rate and help you achieve high standards consistently.

You might be thinking, “All those benefits sound great, but how much will it cost me?” Good news — increasing throughput and efficiency through automation doesn’t have to “break the bank!”

The MGX Carton Former and Carton Erector is a competitively priced carton-forming solution that can increase consistency and production capacity without the substantial investment that many believe is necessary.

Meet the small but mighty MGX carton-forming machine

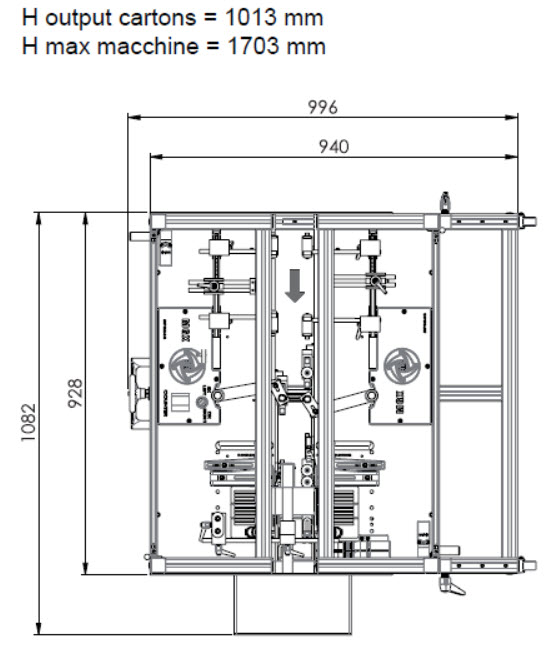

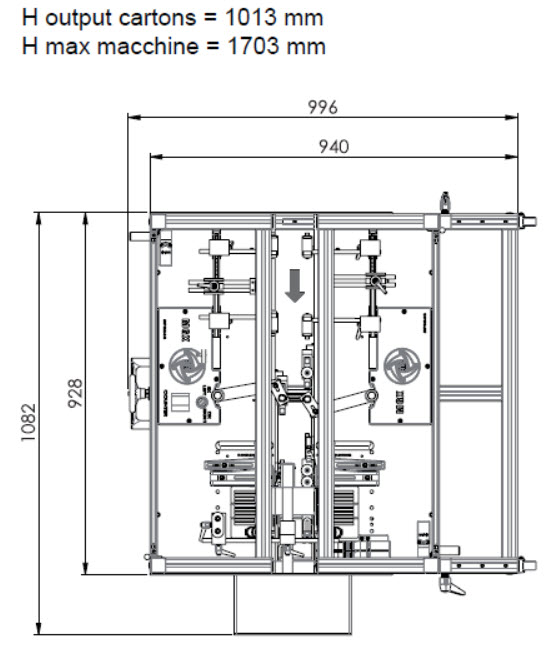

The MGX is a small-footprint carton former and carton erector explicitly designed for small and medium-sized businesses.Main features of the MGX carton former:

- This electro-pneumatic machine with PLC control logic is equipped with a piece counter and a stop when a minimum load of carton/tray blanks is detected.

- It is suitable for the partial formation and automatic coding of cartons/trays of various sizes.

- It can be used in the pharmaceutical, cosmetic, and food sectors.

- Packages small quantities of products with quick and easy format changes.

- It can automatically form carton and tray blanks of any weight and code on both closing edges. The carton/tray is always closed from the back side. The coding can occur either on both edges or the chosen edge.

- Mechanical speed: 1440/hour

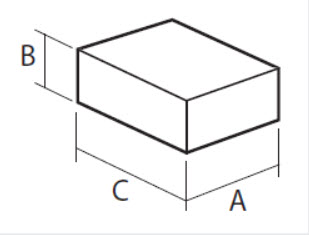

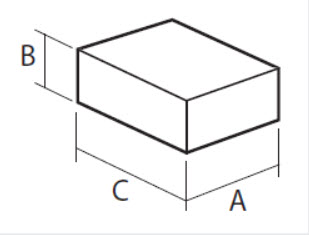

- Size range: Minimum 17 x 20 x 60 mm (0.66 x 0.78 x 2.36 Inches); maximum 120 x 80 x 250 mm (4.72 x 3.14 x 9.84 Inches)

SPECIFICATIONS

- Mechanical speed : 1440/hour or 240 pieces per minute

- Power absorbition : 1.2 kW

- Pneumatic air : 5 lt/min, 5 bar

- Weight : +/-150 kg

- Size range : Min A-17 B-20 C-60 A+B - / Max A-120 B-80 C-250 A+B-200

Check out this video to see the MGX carton former in action.

COVID Supply Chain Warning Due to global challenges including COVID and Climate Change affecting all businesses, prices are subject to change because of supply chain disruptions, shipping delays, labor shortages, material shortages, and inflationary pressures. If you place an order, and there is an increase in a price from that shown, we will alert you before processing the order.

Specifications

| Manufacturer Part #: | MGX |

SPECIFICATIONS

| |