Description

Tray Sealer | PP-YTM-300-4 Preferred Pack Semi-Automatic Manual Tray Sealer with One Cavity measuring 135 × 135 mm (5.3 x 5.3 Inch) with a Fast Cycle Time of 6 seconds and Production Rate of 8-10 Trays Per Minute

Ideal for:

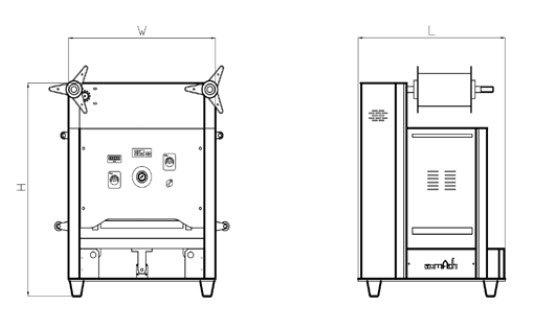

The Preferred Pack Model PP-YTM-300-4 is a Semi-Automatic, partially Manually operated “Shuttle Style”, Tray Sealer that will automatically seal Lidding Film to a tray and automatically die-cut around the perimeter of a tray for a nice clean retail appearance. This is a fast, efficient and easy way to seal low to medium quantities of trays at an affordable price. Just look at the specifications and the pricing on the different models and accessories. The YTM-300 has a Fast Cycle Time of 6 seconds and can produce 8-10 Trays Per Minute with the ability to process one tray per cavity in a Tooling Set. Each additional cavity multiplies your Tray Production Rate. So, if you have a one cavity unit, you will produce 8-10 Trays per minute. If you have a two-cavity unit, you can produce 16-20 Trays Per Minute. Your production multiplies accordingly with the number of cavities and hence trays you put into each Tooling Set holding your tray(s). For convenience, the YTM is designed to be used as a tabletop or a bench unit.

OPERATION (See video below.)

After you load a tray, push the handle of the Tooling Set with tray(s) in the cavity(s) into the YTM to start a sealing cycle. Once the tray(s) are inside the YTM, Lidding Film automatically advances and is automatically applied to seal a tray. A die-cut is then automatically done around the perimeter of each tray to make a nice clean cut(s) leaving no scrap. Scrap film is automatically wound up on a scrap wheel. Sealing process completed, you then pull the Tool Set out and remove the sealed tray(s) from the cavity(s). To continue production, repeat the above steps, load trays, push the Tool Set into the YTM, the film automatically advances and starts a new cycle.

Standard Features Include:

SPECIFICATIONS

- Model :PP-YTM-300-4

- Maximum tray height :110 mm (4.3 Inch)

- Maximum tray length×width : sealing 1 at a time - 135 × 135 mm (5.3 x 5.3 Inch)

- Cycle time : 6 seconds

- Voltage : AC220V / AC110V

- Machine dimensions : 550 × 640 × 650 mm (22 x 25 x 26 Inch)

- Weight : 120 kg (264 lbs)

- Max Film diameter : 220 mm (8.7 Inch)

- Air pressure : 0.6-0.8 Mpa (1 CFM @60 PSI)

- Total power : 1.8 kw (1800 watts)

Configuration

- PLC :MITSUBISHI FX2N

- Pneumatic accessories :Airtac

- Main body material :304 stainless steel

- Mold material:6061 aluminum

- Electrical accessoriesSchneider

- Thermostat : MH-PT100

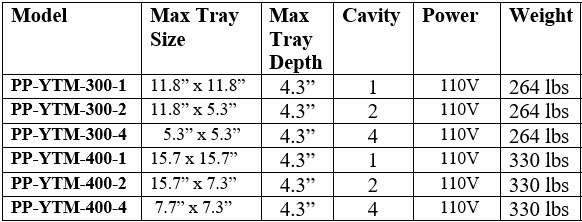

Other Preferred Pack Model PP-YTM-300 Semi-Automatic Manual Tray Sealer

For Order PP-YTM-300-1 Max Tray Size 300 × 300 mm (11.8 x 11.8 Inch)

For Order PP-YTM-300-2 Max Tray Size 300 × 135 mm (11.8 x 5.3 Inch)

Additional Tooling

Additional Tooling for PP-YTM-300 and PP-YTM-400 Series Preferred Pack Semi-Automatic Tray Sealers

OPTION

Trays for PP-YTM-300 and PP-YTM-400 Series Preferred Pack Semi-Automatic Tray Sealers

Lidding Film for PP-YTM-300 and PP-YTM-400 Series Preferred Pack Semi-Automatic Tray Sealers

Date Code Ribbon Printer for PP-YTM-and PP-YTA Series Preferred Pack Tray Sealers

Trays and Lidding Film quoted upon request.

Optional Installation: To be performed by factory-trained service engineer. The customer is responsible for the uncrating of machine and placing it in position on floor. The customer is also responsible for bringing the necessary air and electrical requirements to the machine. The service engineer will set up machines, train operators and maintenance personal on all machine functions and routine maintenance procedures. The service engineer will make sure customer is running production and the customer is required to sign off on installation after completion. Installation and training is billed at prevailing service rates of $120.00 per hour for labor ($960.00 per day) and $100.00 per hour for travel time. Air fare, hotel, car rental and stay expenses are additional if required.

Product Samples: Are required to make sure your equipment is set up and runs properly prior to shipment. 5-10 samples of each tray size and film are required for evaluation and testing.

Specifications

| Manufacturer Part #: | PP-YTM-300-4 |

| Dimensions (LxWxH): | 22.00in. x 25.00in. x 26.00in. |

SPECIFICATIONS

Configuration

| |