X-Ray Inspection Equipment | MEKI ONE Food X-Ray Inspection Machine

Call Toll Free: 877.336.6877 for Pricing

Availability

Online

In Store

Same Day

Description

X-Ray Inspection Equipment | MEKI ONE Food X-Ray Inspection

With X-ray inspection, you can protect your customers and brand image by detecting multiple hazardous foreign bodies and quality defects (such as missing pieces or broken products) from food packaging lines. Using X-ray systems to inspect individual food packages prevents costly product recalls and reduces the number of reclamations and ensures that only the safest and high-quality products reach consumers.

Also, when establishing a product safety or HACCP/HARCP plan or obtaining third-party food safety certifications, such as BRC, SQF, and IFS, food producers and packers are required to implement in-line inspection systems to fulfill the safety requirements. MEKI™ ONE works as such a system by inspecting each individual food package, detecting hazardous foreign bodies (metals, glass, stones, and even dense plastics) and unwanted quality defects from them.

ALL YOU NEED FROM A CRITICAL CONTROL POINT IN ONE

The MEKI™ ONE brings all the benefits of an X-ray inspection system in one compact package. Combining the superior X-ray sensitivity and the smallest footprint, the system also comes equipped with multiple sensors that monitor the system’s safety and operational functionality. One example is the rejection confirmation that monitors that each non-conforming product is rejected accordingly and only the safe and high-quality products pass this critical control point.

Watch the video below to learn more about the functionalities of the MEKI™ ONE system.

The system makes it easy to implement better inspection solutions to food packaging lines while also fulfilling and even exceeding any global quality standard that food manufacturers and co-packers may encounter when expanding their business. The system is designed for the inspection of primary packaged food products because it will provide excellent detection performance and pack-for-pack traceability, both of which are key factors in today’s food business. Equipping individual packaging lines with the MEKI™ ONE system ensures that you will benefit from all of the aspects of this best value safety and quality inspection solution.

FEATURES

- Critical Control Point Based on X-Ray Technology, Providing Safety, Quality and Traceability

- Suitable for various food industries

- Detecting foreign object and quality defects in food products

- Integrated and Automatic product rejection

- Rejection confirmation sensor monitors that each rejection is successful. If the rejection fails, the System stops immediately

- Bin full sensor stops the system and notifies if the rejection bin needs to be emptied

- TO further ensure successful rejection, The system monitors sufficient compressed air pressure

- Safety circuit ensures that the radiation stops if any hatch or door is opened

- Additional hand sensor protect that no body parts enter the system when X-Ray is on

- The Meki-One is designed for individual packaging lines offering best value and performance.

- X-Ray Power: 100W

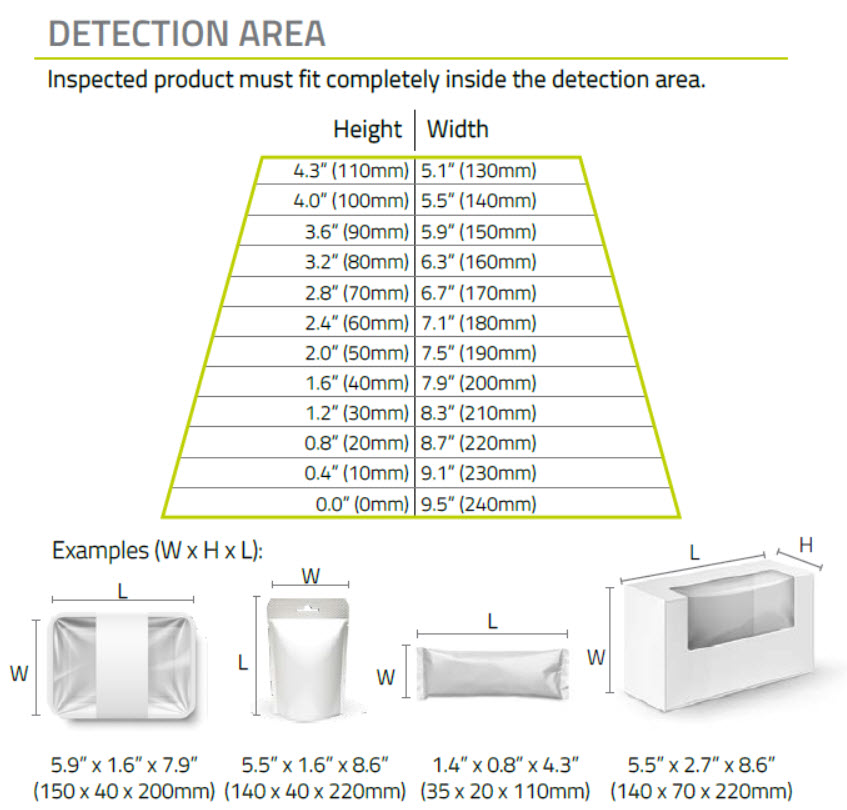

- Detection Area: 9.4 W x 4.33 H Inch (239 W x 110 H mm)

- Conveyor Speed: up to 258 ft/min

- Operating System: Windows 10

- HMI: 12 Inch Color TFT LCD Screen

- Material: Stainless Steel, brushed

- Integrated air reject with bin and standard reject confirmation

SPECIFICATIONS

- Detection area (W x H) : 9.5” x 4.3” (240mm x 110mm)

- Conveyor speed: min. 0.3 ft/s (0.1 m/s) max. 4.3 ft/s (1.3 m/s)

- Conveyor load capacity: max. 3 kg

- X-ray power: 30-60 kV, 0.2–2.5 mA, max 100 W

- X-ray leakage: less than 1 ?Sv/h

- Detector: Linear scanner, resolution 0.4 mm

- Software: Mekitec X-Ray Inspection System SW

- Operating system : Windows 10

- Connectivity: USB, Ethernet

- HMI: 12” Color TFT LCD Screen

- Operation Temperature: 0–35 °C ambient

- Cooling: Optional air conditioner

- IP rating: IP54

- Relative humidity: 30-85%, non-condensing

- System power supply: 110-230 VAC, 50/60 Hz

- Dimensions (W x D x H) : 47”/50” x 28” x 79” (1200/1280 x 715 x 2000 mm)

- Weight: 342 lbs (155 kg)

- Material: Stainless steel, brushed

- Reject: Integrated air reject with bin and standard reject confirmation

- Options: Two conveyor model, push-arm reject, hand sensors* and full reject confirmation

- System conveyor: EU and FDA food use approved conveyor belt

- Radiation protection: EN 61010-02-091, FDA CFR 21 part 1020.40

- Safety switches: Safety circuit CAT 3, Performance Level PL d

DEMO VIDEO

COVID Supply Chain Warning Due to global challenges including COVID and Climate Change affecting all businesses, prices are subject to change because of supply chain disruptions, shipping delays, labor shortages, material shortages, and inflationary pressures. If you place an order, and there is an increase in a price from that shown, we will alert you before processing the order.

Specifications

| Manufacturer Part #: | MEKI ONE |

| Dimensions (LxWxH): | 28.00in. x 50.00in. x 79.00in. |

SPECIFICATIONS

| |